Aug 06,2025

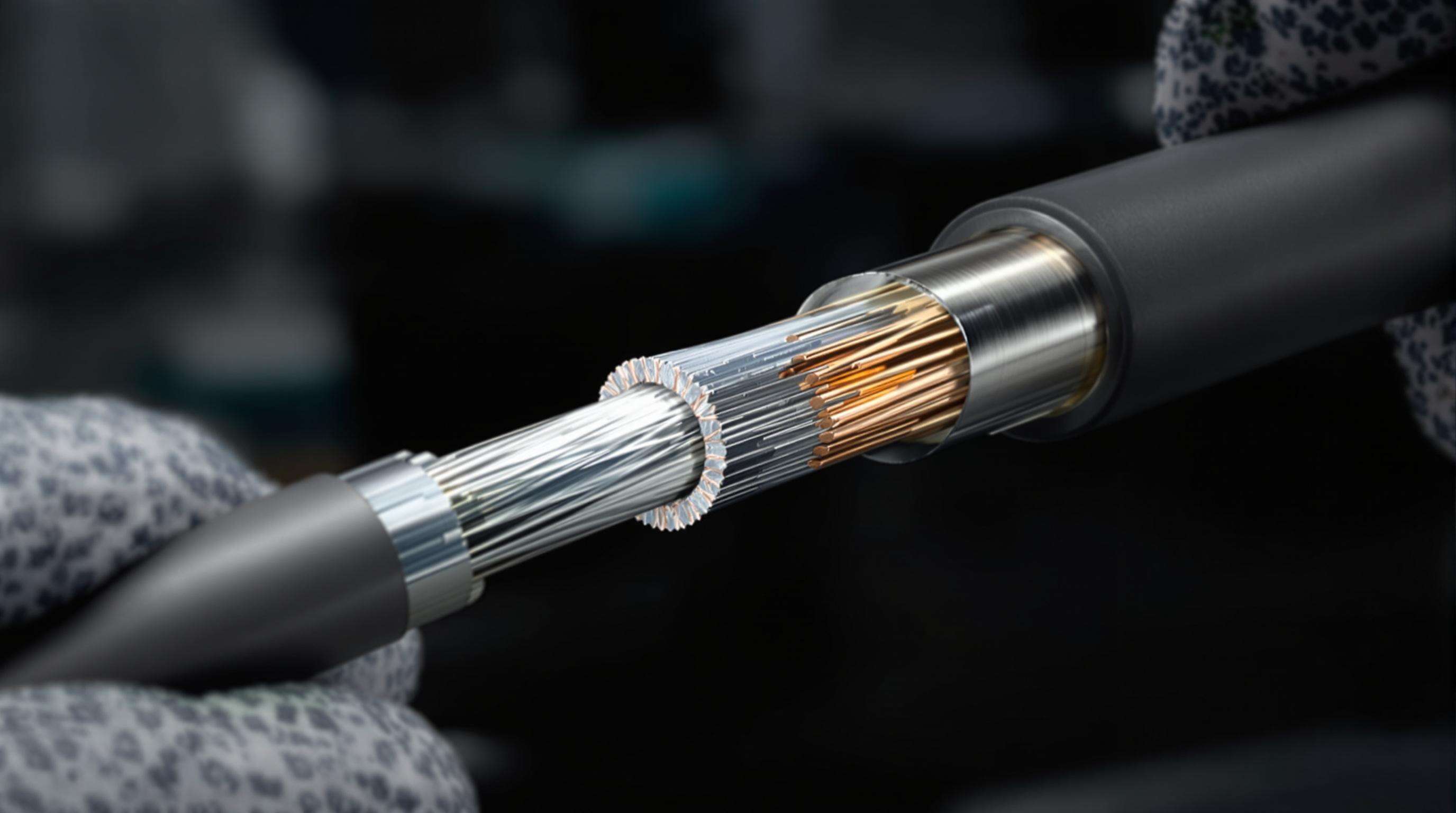

Copper Clad Aluminum or CCA wire basically has an aluminum center covered by a thin copper coating. What this does is combine the light weight advantage of aluminum, which weighs about 30 percent less than regular copper, with copper's better surface conductivity properties. The result? Electrical performance that's pretty much on par with solid copper wires, but with around 60 to 70 percent less actual copper needed according to Wire Technology International from last year. Then there's CCAM wire which takes things further. These wires use improved bonding methods so they don't peel apart when bent back and forth repeatedly. This makes them much more reliable for applications where the wiring gets moved around a lot or experiences constant motion.

When manufacturers replace around 90 percent of the conductor mass with aluminum instead of copper, they end up using much less copper but still get about 85 to 90 percent of what pure copper can do electrically. For big cable purchases over 1,000 meters long, this means companies save roughly 40% on materials according to Cable Manufacturing Quarterly from last year. What's interesting is how the copper coating actually stands up better against rust than regular aluminum wires would. That makes CCAM cables last longer especially when installed where there's lots of moisture or chemical exposure problems.

CCAM has a conductivity rating around 58.5 MS/m which puts it right up there with pure copper that ranges from about 58 to nearly 60 MS/m. The numbers look much better than what we get from copper coated steel, which typically sits somewhere between 20 and 30 MS/m. For frequencies above 3 GHz, most engineers still reach for pure copper as their go to material. But when looking at broadband systems running under 1.5 GHz, CCAM works just fine in practice. What makes this material stand out is how it balances good performance with real money savings and lighter weight too. That's why many companies are turning to CCAM for things like last mile connections within buildings or between structures where some small amount of signal loss isn't going to cause major problems.

CCAM wire combines aluminum core with copper cladding in its hybrid design, which means about 40 to 60 percent less copper is needed compared to regular solid copper wires. Despite using less material, it still keeps around 90% of what makes copper so good at conducting electricity. For manufacturers producing these wires in bulk quantities, this translates into real money saved. The production cost drops somewhere between $18 and $32 for every thousand feet made, something that adds up fast when telecom companies need to install massive networks across regions. And there's another benefit too: since CCAM cables weigh about 30% less than traditional ones, shipping them becomes cheaper as well. Logistics companies report savings ranging from $2.50 to almost $5 per spool during those long hauls across country, making transportation budgets stretch further without compromising quality standards.

Copper prices have swung wildly by about 54% since 2020, making CCAM wire an attractive option for companies wanting to protect themselves from these ups and downs. Aluminum stands out as much more stable, with price changes only 18% smaller than copper according to LME data from last year. This stability helps manufacturers keep their costs predictable when signing those long term contracts. Companies that switch to CCAM see around 22% fewer unexpected expenses during big projects. Think about something like rolling out 5G networks or expanding broadband across entire regions where they need tens of thousands of cables. These real world applications show how switching materials can lead to better control over project budgets and overall financial planning.

CCAM works with what's called the skin effect. Basically, when signals have high frequencies, they tend to stick to the outer part of conductors rather than going all the way through. This means the copper coating on CCAM cables does most of the work for transmitting signals efficiently. When looking at frequencies around 3 GHz, about 90% of the electrical current stays right in that copper layer. The difference in performance compared to solid copper wires isn't huge either, only about 8% signal loss every 100 meters or so. But there's a catch. Aluminum has higher resistance than copper (around 2.65 × 10⁻⁸ ohm meters versus copper's 1.68 × 10⁻⁸ ohm meters). Because of this, CCAM actually loses about 15 to 25% more signal strength in those middle frequency ranges between 500 MHz and 1 GHz. That makes CCAM not as great for situations where signals need to travel far distances or carry strong power levels in analog systems.

While the copper cladding protects against oxidation in dry conditions, CCAM is less robust under mechanical and environmental stress than pure copper. Independent testing highlights these differences:

| Property | CCAM Wire | Pure Copper |

|---|---|---|

| Tensile strength | 110–130 MPa | 200–250 MPa |

| Bend cycles before fail | 3,500 | 8,000+ |

| Salt spray corrosion | 720 hrs | 1,500+ hrs |

In coastal environments, CCAM cables often develop patina at connection points within 18–24 months, necessitating 30% more maintenance than copper-based systems.

CCAM works great for short range high frequency stuff like those little 5G cells in cities. At 3.5 GHz it only loses about 1.2 dB per 100 meters which fits right into what LTE-A needs. But there's a catch when it comes to Power over Ethernet (PoE++). Because CCAM has roughly 55% more DC resistance than regular copper, it gets tricky for longer runs beyond 300 meters where the voltage just drops too much. Most installers have found that mixing things up helps. They use CCAM for the drop cables going to individual devices but stick with pure copper for the main trunk lines running through buildings. This mixed method cuts down on material costs somewhere around 18 to 22 percent while keeping signal loss under 1.5 dB. It's basically finding that sweet spot between getting good performance without breaking the bank.

Global spending on broadband infrastructure is expected to hit around $740 billion by 2030 according to Ponemon Institute research from last year, and telecom companies are increasingly turning to alternatives like CCAM wire to cut costs. Compared to traditional copper cables, CCAM reduces material expenses by roughly 40 percent while weighing about 45 percent less, which speeds things up when installing new lines in overhead or final stretch connections. What really matters though is that CCAM retains approximately 90% of what copper can do in terms of conducting electricity, making it work well for coaxial systems ready for 5G rollout. This becomes especially valuable in crowded city areas where getting heavy copper cables into tight spaces creates all sorts of headaches for installers who need something that bends easier and handles better during actual field work.

The jump in copper prices has been staggering really, going up around 120% since 2020 alone. Because of this many telecom companies have switched to CCAM instead. About two thirds of them actually. Aluminum makes sense here because it's just so much more plentiful than copper. Plus refining aluminum takes way less energy too, roughly 85% less according to industry reports. The carbon footprint difference is huge when we look at actual numbers. For CCAM products, it's about 2.2 kilograms of CO2 per kilogram produced compared to nearly 8.5 kg for regular copper cables. Another big plus point for CCAM is that almost all of it can be recycled again later on. And unlike copper which fluctuates wildly in price year after year, CCAM stays pretty stable with only about plus or minus 8% variation annually. This stability helps companies meet their green targets while keeping costs predictable. Many European countries are already pushing for greener networks through policies aligned with the Paris Agreement framework. As a result, over ninety percent of telecom operators across the EU now require low carbon materials for any new infrastructure projects they undertake these days.

CCAM wire has become a go-to solution for citywide broadband projects thanks to its impressive 40 percent lighter weight compared to traditional options. This makes it much easier and safer to install overhead in crowded urban environments. The lightweight nature works wonders in apartment complexes with multiple floors and old neighborhoods where the existing infrastructure simply can't handle the bulk of standard copper cables. Installers report that working with CCAM cuts down their job time somewhere between 15 and 20 percent, which means service providers can bridge those stubborn last-mile connections without breaking a sweat or causing unnecessary disruption to communities.

One big telecom company in Europe saved around €2.1 million each year after swapping out old copper distribution cables for CCAM versions in 12 different city areas as part of their national FTTH expansion. After installation, tests showed that signal loss stayed under 0.18 dB per meter at 1 GHz frequencies, which is actually comparable to what they used to get from copper. Plus, because these new cables are lighter, crews could install them 28% quicker when running them along power lines. What started as just one project has now turned into something other companies look at when planning their own upgrades. The results show that CCAM materials really work well against tough performance requirements and still manage to cut costs and simplify logistics at the same time.

CCAM wire is a type of coaxial cable that features a copper cladding over an aluminum core, which reduces copper consumption while maintaining good conductivity and performance.

CCAM wire provides similar electrical performance to pure copper cables for certain applications, especially at frequencies below 1.5 GHz, while offering cost advantages and reduced weight.

CCAM cables perform well for high-frequency applications up to 3.5 GHz but may not be suitable for long-distance transmissions due to increased signal attenuation compared to pure copper.

While CCAM wires offer corrosion resistance, they are less durable than pure copper cables under mechanical stress and require more maintenance in coastal environments.

Telecom companies are adopting CCAM wire due to its cost-effectiveness, reduced weight, and sustainability benefits, helping them meet green targets and manage project budgets effectively.

Tailored advice, perfect fit solutions.

Efficient manufacturing, seamless supply.

Rigorous testing, global certifications.

Prompt assistance, ongoing support.