Aug 01,2025

Stranded wire is basically just lots of tiny copper wires all twisted together, which creates something really flexible that works great in today's lighting setups. The way these wires are arranged actually helps cut down on stress when they get bent around corners, so electricians can run them through walls, pipes, and those awkward spots where traditional wiring would break down. For homes and businesses looking at energy savings, this type of wire stands out because it handles vibrations better, doesn't crack under temperature changes, and stays reliable even after people keep adjusting light fixtures over time. That means fewer problems down the road with connections failing or lights flickering unexpectedly.

While solid wire may have a lower initial cost, stranded wire reduces labor and maintenance expenses in dynamic lighting setups where fixtures are repositioned or upgraded.

Using stranded wire makes installation go quicker and safer overall. Electricians working on retrofits often finish jobs about 20 percent faster because the wires are easier to handle and wrap around those awkward junction boxes or track systems they encounter all the time. When electricity flows through multiple strands instead of one solid conductor, it spreads out better which means fewer hot spots forming. That matters a lot in places where people constantly walk around like office buildings and stores. The way these wires distribute the load evenly actually helps protect delicate equipment too. Dimmer switches and those fancy smart lighting controllers last longer since they don't get hit with sudden temperature changes that wear them down over time. Without this protection, these components would fail much sooner than expected.

LED lights today use around 40 percent less electricity compared to those old CFL bulbs, based on what the Department of Energy reported back in 2023. Because they draw so much less power, electricians can actually get away with using thinner wires for installations. Most folks end up going with something between 18 and 14 AWG when working on these kinds of projects. But wait there's a catch with CFLs too. When dealing with circuits that still have them running, technicians need to knock down the capacity by about 20%. Why? Well those CFLs create all sorts of electrical noise plus their internal components aren't as efficient as we'd like. This becomes really important problem when trying to upgrade older buildings where people just want to swap out the lighting without rewiring everything from scratch.

According to the National Electrical Code or NEC for short, voltage drop needs to stay under 3 percent when dealing with those low voltage lighting setups. Let's look at a real world example: take a 24 volt LED circuit that pulls 5 amps across 50 feet of cable. If someone uses 14 gauge stranded wire, they'll only see about 1.2 volts lost along the way. But switch to 16 gauge and suddenly there's a bigger problem with 2.8 volts disappearing instead. That kind of difference can really mess up how well the lights actually work. Another thing worth noting is that stranded copper has around 15 percent less skin effect impedance at standard 60 hertz frequencies compared to solid wire options. This makes a noticeable difference in efficiency particularly important for those dimmable 12 volt systems where every bit counts.

Looking at NEC Table 310.16 from the 2023 edition, we find that 16 AWG stranded wire loses around 23% of its ampacity capacity when exposed to ambient temperatures exceeding 40 degrees Celsius. Things get even worse when this wire is bundled together with three or more other current carrying conductors, where the ampacity drops down by approximately 30%. Some recent thermal imaging research has actually demonstrated something interesting too. Stranded wire bundles tend to run about 10 to 15 degrees cooler compared to their solid core counterparts during those long continuous 6 hour load periods. This temperature difference helps extend the life of the insulation material quite significantly while also satisfying more stringent fire safety requirements in building codes across different regions.

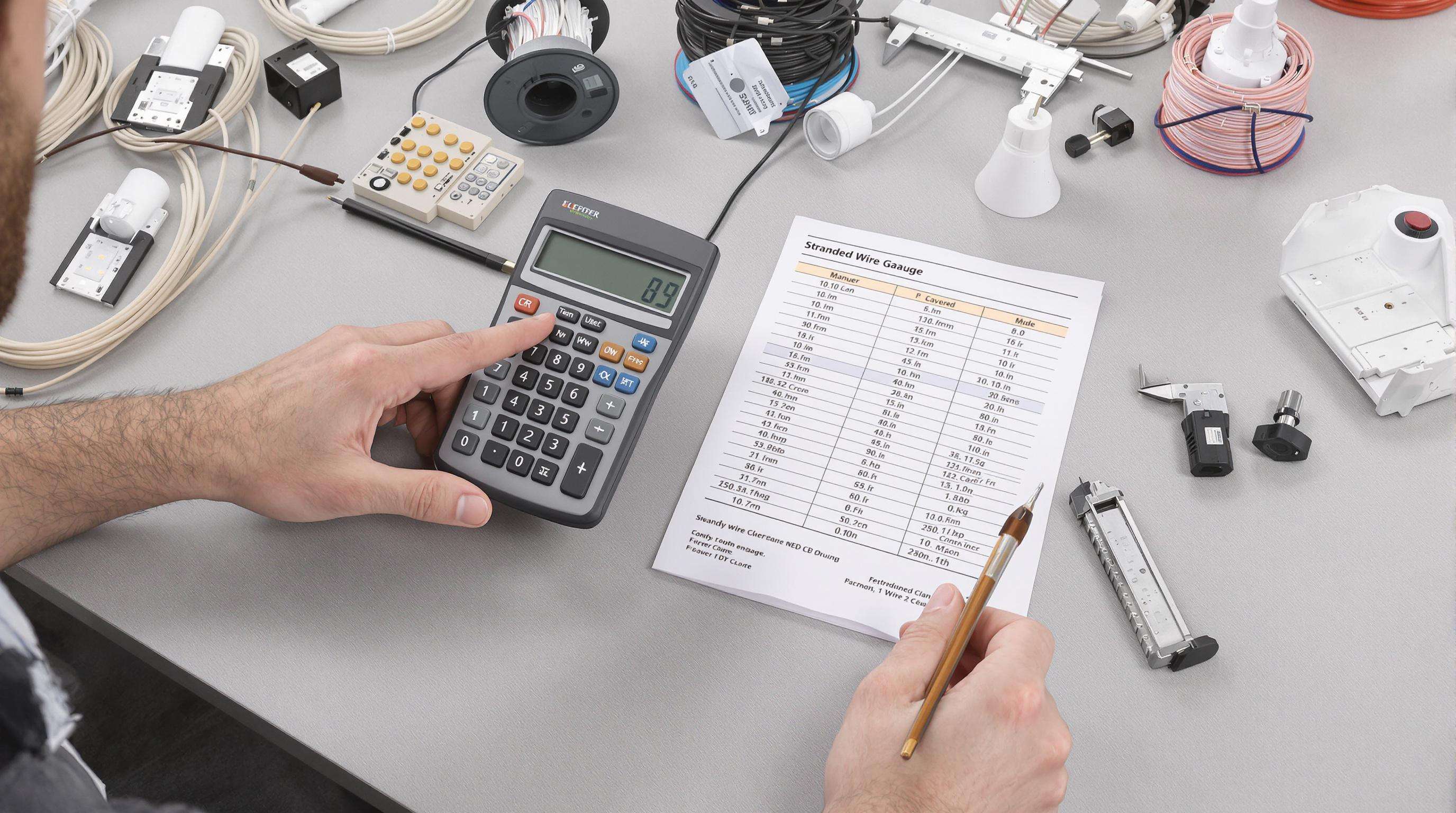

Getting the right stranded wire size means pairing American Wire Gauge measurements with their metric equivalents in square millimeters. For energy efficient lighting setups, we typically see 18 AWG wires at around 0.823 mm squared used for those small LED strip lights, all the way up to 12 AWG which measures about 3.31 mm squared for bigger commercial installations. According to some recent studies last year, 14 AWG stranded wire measuring approximately 2.08 mm squared works well for standard 15 amp residential lighting circuits without causing significant voltage loss issues down the line.

| AWG | Cross-Section (mm²) | Max Current (Amps) | Typical Use Case |

|---|---|---|---|

| 18 | 0.823 | 7 | LED strip lighting |

| 16 | 1.31 | 10 | Under-cabinet fixtures |

| 14 | 2.08 | 15 | Recessed residential lighting |

| 12 | 3.31 | 20 | Commercial LED arrays |

How much current a wire can carry really comes down to two main factors: the wire's thickness (gauge) and what it's made of. Take copper stranded wire for example. When it's rated for 60 degrees Celsius operation, a 16 AWG size will safely handle around 10 amps continuously, while going up to 12 AWG doubles that capacity to about 20 amps. Something important to remember though is the National Electrical Code from 2020 suggests reducing this capacity by roughly 15% when several wires are bundled together inside thermal insulation. This becomes particularly relevant with today's LED lighting installations where it's common practice to run multiple circuits through shared conduits, making proper derating calculations absolutely essential for safe electrical work.

When converting AWG measurements to metric units, there's a mathematical formula involved: mm squared equals approximately 0.012668 multiplied by 92 raised to the power of ((36 minus AWG) divided by 19.5). But nobody really wants to calculate that manually all day long. That's why international standards like IEC 60228 have made things easier with standard sizes already defined for us. Most European lighting installations will commonly see cables rated at 1.5 mm squared which is roughly equivalent to 16 AWG, or the bigger 2.5 mm squared cables matching around 13 AWG in American terms. Before working on any electrical project though, always check what the local regulations say about wiring. The current carrying capacity numbers can vary quite a bit between US UL standards and European IEC specifications even when talking about wires of identical physical dimensions.

Picking the correct stranded wire makes all the difference when it comes to how well things work in different settings. For indoor stuff like those recessed LED lights we see everywhere these days, most people go with 18 to 16 AWG wire wrapped in flexible PVC insulation. That works great in those tight junction boxes where space is at a premium. When dealing with outdoor path lighting though, things get a bit trickier. The insulation needs to stand up to UV exposure and the copper strands should be tinned to fight off corrosion. Most folks stick with 14 AWG for any 24V runs longer than about 50 feet. And let's not forget about retrofit jobs either. These old systems really appreciate high temperature rated wire that can handle up to 90 degrees Celsius without losing its flexibility. This kind of wire stands up to the heat stress inside those older conduits better than regular options.

Insulation choice impacts both durability and system efficiency:

When retrofitting a large 50,000 square foot office space, switching out the 12 AWG solid core wiring for 10 AWG stranded copper in those main distribution panels made a real difference. Voltage drop across those 200 meter circuits dropped dramatically from around 8.2% down to just 2.1%. The installation crews noticed something else too - they were able to pull cables through those EMT conduits about 23% quicker when working with rope strand conductors. And let's not forget the bottom line impact. This wiring upgrade actually helped cut annual energy consumption by approximately 4.7% simply by reducing those pesky line losses. These kinds of improvements are exactly what the Department of Energy highlighted back in their 2022 LED Retrofit Guidelines, though most electricians already know this works in practice long before seeing it on paper.

Getting wire sizing right starts with looking at three main factors: how much current flows through the circuit, what voltage drop is acceptable, and what temperatures we expect during operation. To figure out the load current, just divide the total wattage of all fixtures by the system voltage. Let's say we have 100 watts running on 12 volts, that gives us around 8.3 amps. When picking a wire size, always go for something from the NEC tables that can handle at least 125% of this number. This extra buffer helps avoid overheating issues when circuits run continuously for long periods. Things get trickier in warmer environments though. If temperatures climb past 30 degrees Celsius, we need to adjust our calculations using those thermal derating factors mentioned in the latest NFPA 70 code. The rule of thumb is that every 10 degree increase cuts down the safe current carrying capacity somewhere between 15 to 20 percent.

Maintaining voltage drop below 3% (0.36V for 12V systems) is critical for LED performance and longevity. Use the standard formula:

Voltage Drop (%) = (2 × Length (m) × Current (A) × Resistance (Ω/km)) / (Voltage × 1000)

Stranded copper's lower skin effect resistance makes it 18–22% more efficient than solid wire in 24V systems over 15 meters (NEMA TS-2022). When voltage drop exceeds 2.5%, upgrading to a larger gauge preserves lumen output, as each 0.1V loss reduces brightness by 4–6%.

0.36V / (2 × 50m × 8.33A) = 0.000432 Ω/m

A 14 AWG stranded wire (2.08 mm²) has a resistance of 0.00328 Ω/m—too high for this run. Upgrading to 12 AWG (3.31 mm², 0.00208 Ω/m) reduces voltage drop to 2.1% (0.25V), maintaining full brightness. This proper sizing reduces energy waste by 9–12% compared to undersized cabling.

| Wire Gauge | Cross-Section (mm²) | Max Current (A) | Max Length @3% Drop (12V) |

|---|---|---|---|

| 16 AWG | 1.31 | 10 | 28m |

| 14 AWG | 2.08 | 15 | 45m |

| 12 AWG | 3.31 | 20 | 72m |

This table demonstrates how increasing wire gauge extends maximum circuit length while adhering to NEC safety and efficiency standards.

Stranded wire offers flexibility, reduced risk of strand breakage, better handling of vibrations, and resilience against temperature changes, making it ideal for dynamic lighting installations.

Stranded wire handles lower electrical loads effectively, distributes current evenly to avoid hot spots, and reduces voltage drop, enhancing energy efficiency.

Its flexibility speeds up installation and protects equipment like dimmer switches from temperature fluctuations, prolonging their operational life.

Consider the current load, voltage drop, ambient temperatures, and whether the wire will be bundled with others when determining the right size.

Materials like PVC offer cost benefits, while XLPE provides superior thermal stability and reduces leakage currents, crucial for energy-efficient setups.

Tailored advice, perfect fit solutions.

Efficient manufacturing, seamless supply.

Rigorous testing, global certifications.

Prompt assistance, ongoing support.